Flite Technology, Inc.

| KORTECK Cormex-24 Special Plating- Electroless nickel with silicon or boron particles. Cormex-24tm, double and triple industrial hard chrome plating available to eliminate all porosity. High polished and buffed surfaces as required. |

| Glass Commander and Koralloy Screws special purpose metals- For screws subjected to glass-filled and other abrasive circumstances. Stainless Steel, Nickle-based superalloys, and CPM-10V | |

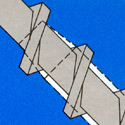

| Root diameters Modified- Compression ratios changed. Flight depths increased or decreased. |

|

Special O.D. Hardfacing- Example: Flitech 300 for extreme abrasive applications and FT/Mo-42 molybdemum where lubricity is required. Specialized hardfacing for elevated temperatures, etc. |

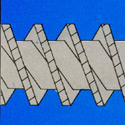

| Mixing Sections- All types rebuilt, manufactured or retrofitted on existing screws.. |

| Special Root Coatings, Weldments and Treatments- Heat treating, nitriding, stelite and Colmonoy Ceramic wearsurfacing. Kortung Nitratech and Diamond Flite. |

| Flights Added- Have dead area where material is hanging up and burning or degrading? Flights extended through this area, correcting the problem. |

| Pressure Tests- Screw pressure tested for clear cooling holes, root cracks, and proper tip and “O” ring fit. | |

| Crammer Screws- Manufactured or rebuilt. Two piece sectioned and single. |

| Partial Flight Rebuilding- Have only certain area where flights wear and don’t want to pay for entire rebuilding cost? No problem; we’re out to save you money whenever possible. Two different hardfacing can be applied to the same screw, maximizing flight protection where necessary. | |

| Hardfacing Thickness Increased- For extreme abrasive wear where units can still run with notable flight O.D. loss and where normal screws are unusable because of accelerating flight abase material wear. |

| Geometrical Profiling - for Feed screws. Root rebuilding, compression changes , and Korgardtm protective coatings for worn root diameters. |