|

Non-Destructive Testing – Before or after repairs on request.

Eliminates wasting money on severely cracked on fatigued units which

are not worth repairing. |

|

Test Methods Include- X-ray ultrasonic magnetic particle,

dye penetrant gamma ray, ect. |

|

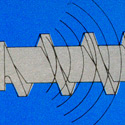

Hardness Evaluation- Screw base Materials and hardfaced areas. Planting

and coating checked for thickness, lubricity hardness and porosity |

|

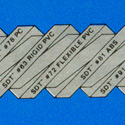

Micro-Photography- Screws and barrels not holding up? Make sure you

are getting the material you ordered. Even then, improper welding and

bonding techniques can diffuse soft substrate atals into hardfacing

overlay, reducing wear protection. |

|

Metallurgical Breakdowns- Investigate and solve problems involving

premature wear and breakage. |

|

Wear Analysis- Comparisons and compatibility studies. |

|

Instant Quotes- Most repair, rebuilding and manufacturing jobs can

be discussed by phone with a verbal price given and a confirming quote

sent out immediately by U.S. mail, TWX, FAX machine or by e-mail.

|

| Free Inspection- before any work is

performed, you parts are thoroughly checked for any wear, dimensional

discrepancies and/or structural damage. Then we discuss your

requirements and specifications with you and you decide how much

or how little work is performed. A written guaranteed price

quote is provided if not previously sent.

|

|

Emergency Delivery Service- Even though our normal turn-around time

is pretty impressive, we can accommodate many customers with machines

down with a necessary repair in a day or two. Please note,

this is the only number monitored 24 hours a day, (305) 631-2050. |

| Reduced Costs- As a result of our high volume of orders and keeping

up with the most modern innovative machining techniques, thus cutting

labor hours, we remain in a very competitive position regarding prices. |

| Reasonable Air Freight- Due to our large volume of air freight, we are

provided with special discounted rates. Please call ahead for charges. (Often

comparable to land transportation costs.) |

| Fast Freight- Due to our close proximity to Kennedy

Space Center, Disney World, Epcot Center and Patrick Air Force Eastern

Test Range, we have some of the best routing in the nation, resulting

in quick turn-around times. Over 50 freight carriers serve us

directly. |

| On-Site Wear Inspection Available- You may be losing production due to

barrel wear and not even know it. |

| 12 Month Warranty- Flite Technology guarantees its material and workmanship

for a period of 12 months. We urge companies to forward screws

and barrels before they actually need them, so that we can arrange

to have the warranty start on the date of installation when your schedule

is coordinated with our office. |