For Rebuilding a Feed Screw and

Another Company Charge $850?

Brand X

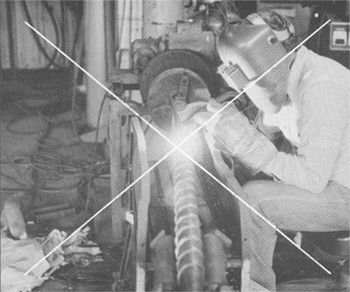

Some companies are

using tig and mig welding to speed up the hardfacing time, but the

result is low Rockwell Hardness, and the screws wear out prematurely. |

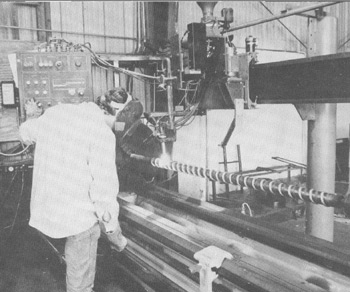

Flite Tech

Flite Technology has invested a considerable amount of money in the latest welding equipment and techniques, providing our customers with a hardfacing with good adherence qualities, fewer voids and cracks which results in a considerably longer screw life. |

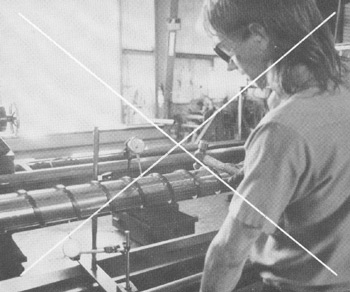

Brand X

Many companies only straighten their screws with

a hammer; YES, we said a hammer. Can you imagine how much stress

the base steel and the hardfacing experience in the process,

and you wonder why your screw has cracks. |

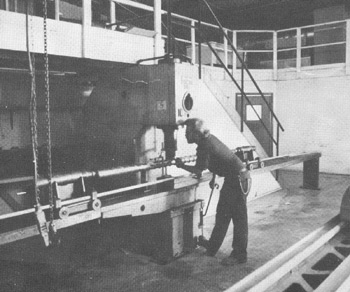

Flite Tech

Flite Technolgy has a hydraulic press especially designed for straightening feed screws and long shafts. Feed screws are treated gently and are brought back to straightness with no damage to the screw’s structural integrity, coating, or hardfacing. |