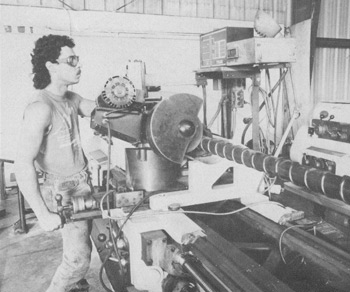

For Rebuilding a Feed Screw and

Another Company Charge $850?

Brand X

A lot of our competitors manually grind the side of the

screw flights after hardfacing or tool the excess material off with

a lathe. When done manually, they cannot be expected to maintain constant

flight widths; and in tooling it off with a lathe, this creates all

kinds of havoc with the hardfacing, causing flights to chip, crack,

peel off, and who knows what else. |

Flite Tech

Flite Technology selects the proper procedure based on the requirements of each hardfacing material used. But the important fact here is that we have flight grinding capacity to properly grind flight sides to maintain proper flight widths, eliminate damage to root diameters and radii that could be caused hardgrinding, and minimize stress to the hardfacing. |

Another problem with this industry

is that some salespeople low bid a job to get it, and then charge extra

for minor repairs. Normally,

everything is covered in our quote, unless there is severe damage not

previously indicated.

|